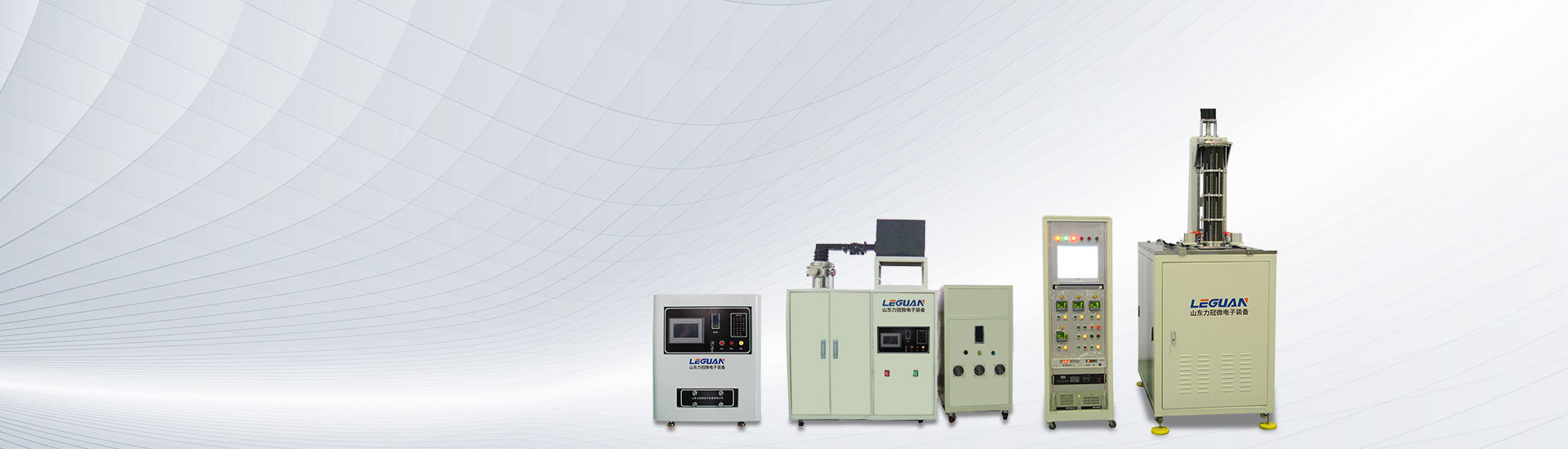

Product display

Gallium Nitride (GaN) HVPE Single Crystal Growth Equipment Horizontal Type

♦For Gallium Nitride (GaN) Single Crystal Growth ♦For epitaxial growth of gallium oxide (Ga₂ Oconstruction), aluminum nitride (AIN), indium phosphide (InP), gallium arsenide (GaAs)

Gallium Nitride (GaN) HVPE Single Crystal Growth Equipment Vertical

♦For Gallium Nitride (GaN) Single Crystal Growth ♦For epitaxial growth of gallium oxide (Ga₂ Oconstruction), aluminum nitride (AIN), indium phosphide (InP), gallium arsenide (GaAs)

PVT Single Crystal Growth Equipment

♦This equipment is mainly used for silicon carbide (SiC), aluminum nitride (AIN) single crystal growth

SiC Seed Crystal Bonding Equipment

♦The bonding technology of seed crystal is to bond the SiC seed crystal to the graphite paper by organic glue. Improving the quality of seed bonding is the primary prerequisite to ensure the growth of high-quality SiC crystals.

♦Microwave plasma chemical vapor deposition (MPCVD) technology, through the plasma to increase the reaction rate of the precursor, reduce the reaction temperature. It is suitable for preparing diamond single crystal and polycrystalline films with large area, good uniformity, high purity and good crystal morphology.

SiC high temperature oxidation equipment

♦It is specially used for the oxidation treatment of silicon carbon compound (SiC), which can realize the high temperature oxidation process of SiC wafer in high temperature vacuum environment. The oxidation process uses wet oxidation gas or N2O, NO, NO2, which is the safest toxic gas oxidation furnace. ♦The equipment is suitable for high temperature oxidation process in the manufacture of SiC-based power devices. ♦The heating chamber and the process chamber are independently sealed and designed to provide the cleanliness of the process chamber.

SiC High Temperature Annealing Equipment

♦It is specially used for ion activation and annealing treatment of silicon carbon compound (SiC), which can realize the active process of SiC wafer in high temperature vacuum environment. ♦The equipment is suitable for ion activation and annealing processes in the manufacture of SiC-based power devices. ♦The heating chamber and the process chamber are independently sealed and designed to provide the cleanliness of the process chamber.

◆ Mainly used for single crystal growth of 4-8 inch arsenide, phosphide and other compounds ◆The equipment is composed of frame, safety support mechanism, heater and control system ◆Able to achieve precise control of Ann's movement and rotation

♦LPCVD equipment is one of the important equipment for the manufacture of semiconductor integrated circuits, mainly used for the growth of polysilicon, silicon nitride, silicon oxide film, it is the raw material gas (or liquid source gasification) with thermal energy to activate the chemical reaction to generate a solid film on the surface of the substrate. LPCVD process is carried out under low pressure, due to the low pressure, the average free path of gas molecules is large, so that the growth of the film uniformity is good, in addition to the substrate can be placed vertically so that the equipment is large, especially suitable for industrial production.

♦LPCVD equipment is one of the important equipment for the manufacture of semiconductor integrated circuits, mainly used for the growth of polysilicon, silicon nitride, silicon oxide film, it is the raw material gas (or liquid source gasification) with thermal energy to activate the chemical reaction to generate a solid film on the surface of the substrate. LPCVD process is carried out under low pressure, due to the low pressure, the average free path of gas molecules is large, so that the growth of the film uniformity is good, in addition to the substrate can be placed vertically so that the equipment is large, especially suitable for industrial production.

♦PECVD is mainly used for thin film growth of silicon oxide (SiO₂) and silicon nitride (SiN4) materials. The working principle is to introduce a high-frequency radio frequency power supply at low voltage, adopt a capacitive coupling method to ionize and discharge the process gas to form a plasma state, and generate a large number of Active groups, these active groups chemically react on the surface of the substrate material and deposit on the surface of the substrate to grow a silicon oxide (SiO₂) or silicon nitride (SiN4) film.

♦The equipment is one of the important process equipment before the semiconductor production line, used for large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and other industries, such as diffusion, oxidation, annealing, alloy and sintering process ♦A variety of process performance requirements for silicon wafer production are designed, which has the characteristics of high growth efficiency and superior product performance ♦It has the advantages of low pollution, small footprint, uniform temperature, large wafer size and high process stability ♦It is mainly used for the preparation process of various oxide dielectric layers such as initial oxide layer, shielding oxide layer, pad oxide layer, sacrificial oxide layer, field oxide layer, etc